-

|

Super Quick-Curing Urethane Waterproofing System

|

|

|

| Dry to the touch in about 20 seconds from spray application, compatible with various configurations and applications |

|

Dry to the touch in about 20 seconds from spray application and cured in about 3 minutes, this urethane liquid-applied membrane waterproofing layer offers excellent physical properties.

It is compatible with a variety of configurations and applications. A mechanized control system facilitates excellent installation accuracy.

|

| A variety of JIS A 6021 Waterproofing and Roof Substrates |

| We are able to provide 10-year warranty for waterproofing work with a variety of substrates. |

| This technique can also be used in conjunction with other substrates, or in new construction. |

|

|

Super Quick-Curing Urethane Waterproofing "GET System"

|

|

|

| Versatile, Economical, and Reliable Waterproofing System |

|

This waterproofing system utilizes compressed air to micro-particulate super quick-curing urethane, which is formed into the waterproofing membrane via multiple collisional mixing.

This provides a membrane twice the thickness of conventional super quick-curing urethane, accomplishing weight reduction (decreased specific gravity). Combining economic efficiency and reliability, this versatile method may be deployed in a variety of fields.

|

| High coating performance suppresses pin-sized hole generation and allows installation without surface smoothing. |

| Cushioning characteristics provide superior sound insulation performance compared to conventional urethane and sheet waterproofing. |

| Further heat insulation effectiveness can be obtained by combining with a high-reflectance top coating. |

| A variety of JIS A 6021 Waterproofing and Roof Substrates |

| We are able to provide 10-year warranty for waterproofing work with a variety of substrates. |

| This technique can also be used in conjunction with other substrates, or in new construction. |

|

|

External Thermal Insulation Waterproofing Technique

|

|

|

| Insulation, Waterproofing, and Building Frame Protection for Cold Climates |

|

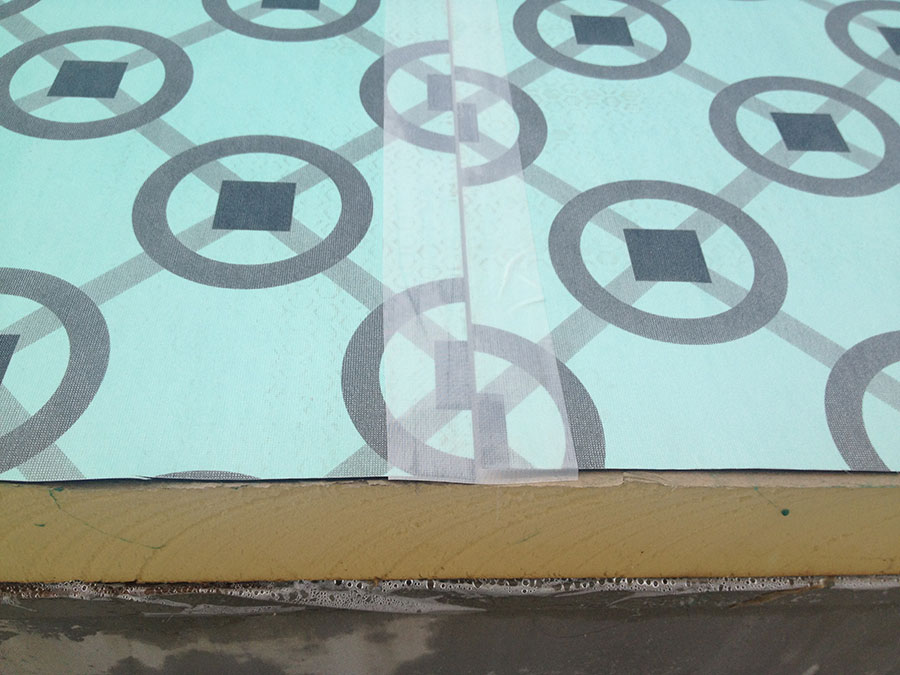

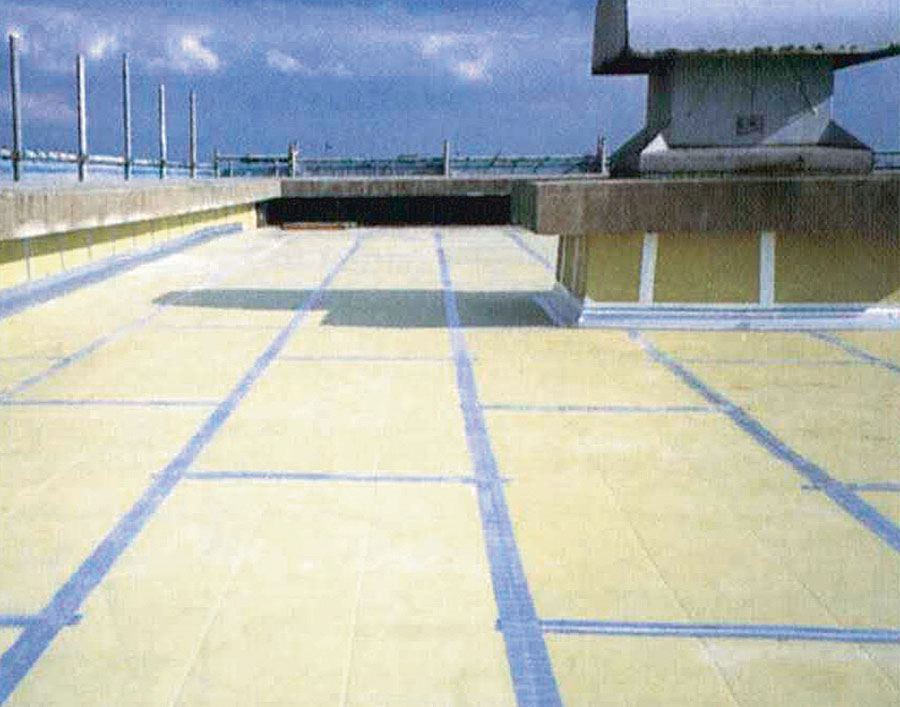

This external insulation method maximizes thermal insulation, waterproofing, and building frame protection characteristics via installation of polymer-modified asphalt sheets over each insulation panel to create a high-performance, polyurethane waterproofing membrane.

Fire Protection - Certification Number DR-0179

|

| Installing the insulation on the exterior surface of the building frame concrete protects the frame from solar impact. By reducing temperature change, we successfully control expansion and contraction of the concrete. |

| Maintainable insulation effectiveness improves air conditioning efficiency. This provides a comfortable indoor environment and saves costs. |

| The polymer-modified asphalt sheet's shock-absorbing properties prevent bulging and tearing when water vapor is discharged through a ventilator. |

|

|

Urethane-Metal Composite Waterproofing Technique

|

|

|

| Versatile "Urethane+Metal" Composite, Compatible with all types of Substrates |

|

The "urethane + metal" composite waterproofing technique is implemented by spraying super quick-curing urethane uniformly over factory formed metal plates that are fixed to the substrate by anchors.

This is compatible with all types of substrates, and minimizes substrate preparation and repair/removal work, facilitating shorter work times.

|

| A mechanized system controls all spray applications of the super quick-curing urethane, facilitating uniform, highly accurate coating. |

| Excellent wind resistance, impact resistance, soundproofing effect, and seismic performance. |

| An ideal external insulation technique, when combined with materials such insulation boards and heat insulation coating. |

|

|

Urethane System Quick-Curing Deck Slab Waterproofing System

|

|

|

| Waterproofing to Extend Service Life of Road Deck Slabs |

|

This high-performance deck slab waterproofing system utilizes a highly-constructable waterproofing material with long-lasting durability and weather resistance to extend the service life of road deck slabs.

|

| Spray-applied polyurethane installation facilitates formation of a seamless waterproofing layer over bridge top surfaces, eliminating the occurrence of harmful blistering to prevent degradation to waterproofing and pavement performance. |

| Excellent durability and weathering resistance |

Solventless installation is environmentally, with short curing times.

It withstands even machine overlay operations, making this method an ideal choice for road maintenance and preservation. |

|

|

Underground Structure Seamless Waterproofing

|

|

|

| Overcomes various underground environment conditions for highly effective waterproofing and protection |

|

High-polymer urethane rubber coating technology provides a high-performance coating for the building frame. This external waterproofing technique overcomes various conditions specific to underground environments that pose major obstacles to conventional waterproofing techniques. This process results in highly reliable waterproofing and protective effects.

|

| Economical method to reduce construction times and costs. |

| Seamless integral waterproofing is formed by super quick-curing spray application. With secure, reliable bonding to irregular configurations, this method excels in durability. |

| The machine-controlled installation system feeds a constant amount of material, achieving uniform, high-quality coating properties unaffected by work environment conditions such as ambient temperature. |

|

|

Open Channel Service Life Extension

|

|

|

| Excellent Durability for Extended Open Channel Service Life |

|

This open channel service life extension technique utilizes super quick-curing polyurethane resin, offering expected weatherability and durability of 30 years or more.

|

| Curing in a matter of seconds, this material offers excellent workability. |

| Roughness coefficient improvement of about 30% can be expected. |

| Surface treatment operations will be minimized during the next repair cycle, leading to significant cost savings. |

|

|

|

| We offer sheet waterproofing applications ideal for environmental compliance and various improvement work. |

This "high-performance, high-quality, and high-functionality" waterproofing system is compatible with substrates of any type. No substrate surface preparation is required, allowing cost reduction and shorter construction schedules.

This system also offers fireproof and fire retardant properties to provide the building protection, as well as high thermal insulating and heat barrier properties to reduce the overall heat load on the building and save energy.

For more information, please feel free to contact us. |

| The high thermal insulating and heat barrier (high reflectivity) properties of our sheet waterproofing method achieve year-round air conditioning and other energy savings, improved habitability such as condensation prevention, and building protective effects. This technique also features fire resistance and fire-retardant properties. |

| The mechanical anchoring technique allows improvement work without altering the existing waterproofing layer, which significantly reduces labor hours and surface preparation costs. Its high wind resistance also provides adequate anchoring strength. |

|

|